Polub nas na Fecebook'u!

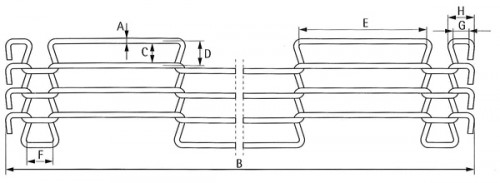

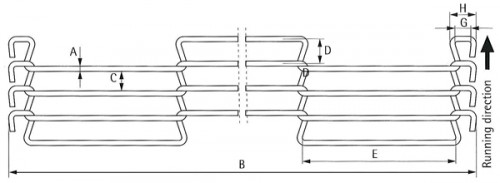

A Wire Ø / mm

B Width / mm

C Mesh width / mm

D Spacing / mm

E Mesh length / mm

F Gear wheel edge / mm

G Final loop / inside / mm

H Final loop / outside / mm

The spacing dimension is measured over 10 graduations with the belt tensioned.

Without gear wheel edge

All dimensions are specified in mm. The dimensions can be varied in steps of 0.005 mm within the specified ranges.

Notes

Table indicates the dimension ranges for standard production. In a few unfavorable cases, some individual dimensions cannot be produced in combination with other dimensions.

In some cases there are production possibilities outside the specified data.

Examples:

• Wider width upon request

• Mesh length of wire 0 0.9 mm and 1.0 mm longer than specified values.

Please consult us in special cases.

Material

Our rod network belts are made of the following alloy types:

1. Patented drawn music wire

2. Cold-drawn stainless steel wire made of:

1.4310 (AISI 301]

1.4571 (AISI 316 Ti) and

1.4401 (AISI 316)

The alloy to be used must match the intended use. All alloys are processed by us in a strain-hardened state. The patented drawn wires have tensile strengths of over 2000N/mm². The high tensile strength gives our products quality advantages over our rivals products. However, this means that demands made on our production process are extremely high.

Patented drawn music wires

Patented means a heat treatment process is carried out upon completion of the cold forming by drawing. This produces a wire which has a high stability but which still has good cold forming properties. Patented drawn music wires can be used in all cases where no high demands are made on the corrosion resistance of the belt. This alloy car also is used if the belt is protected by other materials. Patented drawn music wires can be used in chocolate coating machines, for example.

1.4310 (AISI 301)

This alloy is austenitic steel. Due to the low Cr and Ni contents, this material has a tendency to form marten's site which has ferro- magnetic properties. This alloy is thus slightly magnetic. The marten-site which is produced effects the extremely high stability of this alloy compared to other austenites. 1.4310 (AISI 301)

Is corrosion-resistant under normal environmental conditions. This quality can be used in all cases where corrosion is to be avoided under normal conditions. This alloy could be used, for example, in cases where the belt has to be cleaned with water on a daily basis.

1.3471 (AISI31 Ti) and 1.4401 (AISI 316)

Due to the higher Cr and Ni contents and the lower C content, these alloys are much more corrosion-resistant than 1.4310. These materials are used in special cases where contact is made with aggressive materials/substances, for example, chemicals, lactic acid, fruit acids, etc.

Calculation of the belt width and mesh length

|

Drut-Φ |

Krawędź-S |

Krawędź-B |

|---|---|---|

|

0,90 |

9,7 |

- |

|

1,00 |

10,0 |

- |

|

1,20 |

10,6 |

- |

|

1,25 |

10,8 |

15,4 |

|

1,40 |

15,2 |

15,2 |

|

1,60 |

16,5 |

21,4 |

|

1,80 |

17,2 |

21,2 |

|

2,00 |

18,4 |

- |

|

2,35 |

22,7 |

28,7 |

|

2,80 |

23,2 |

- |

|

3,40 |

35,6 |

- |

|

4,00 |

38,0 |

- |

(attention: same sized meshes or different division)

Belt width

Addition of the mesh length + Gear wheel edge x 2 + Final loops (value: see table) = Outside width of belt.

Mesh length

Outside width of belt - final loops (value: see table) - gear wheel edge x 2 = inside width of belt: number of meshes.

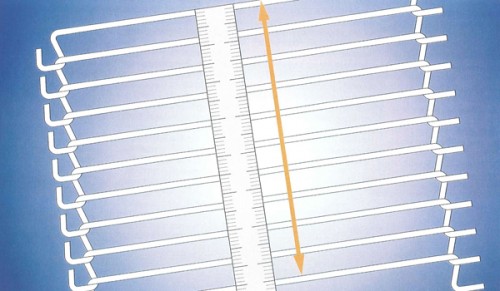

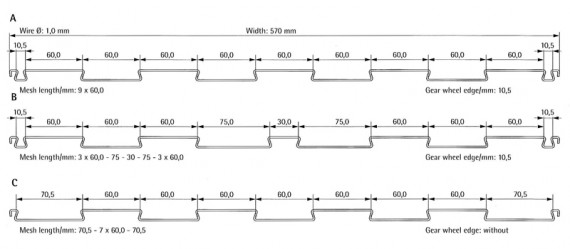

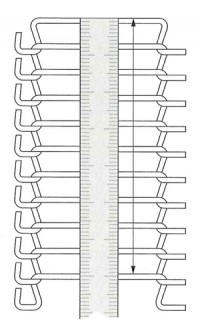

Division of mesh lengths

Mesh lengths can be arranged individually. The examples illustrate 3 different variants. Many other versions are possible.

A) Standard wire mesh belt with nine meshes of the same size and gear wheel edges.

B) Modification of version "A": The middle mesh has a length of 30 mm instead of 60 mm, the two adjacent meshes have a width of 75 mm.

C) Modification of "A": Both gear wheel edges have been dispensed with. To compensate this, the two outside meshes have been extended by the dimension of the gear wheel edges (70.5 mm).

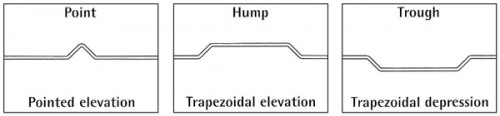

Pointed rod network belts

In addition to the rod network bells for standard applications, the belts are equipped with points, lumps or troughs for special applications.

Elevations or recesses (see adjacent sketches) can be incorporated within the meshes. The layout depends on the intended use:

For example: Sorting, arranging, feeding, point product contact, acsending or inclined conveyors.

Pointed rod network belts can be used, for example, in the confectionery/baker's industry for conveying products whose bases are not coated with anything. The (goods conveyed on the belt only have point contact on the belt elevations.

These very specific belts have numerous construction possibilities with regard to the shape of the points, humps or troughs. Their division can be varied within a wide range in connection with different mesh length combinations.

Distance between the points, humps or troughs within a mesh to one another and to the mesh bend: At least 7.5 mm