Polub nas na Fecebook'u!

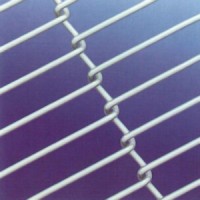

The service life of rod network belts depends on the operating conditions.

There are a few guidelines which must be observed when using rod network belts.

Excessive belt tension

In general the belt tension should be set so that the belt is carried perfectly in the drive sprockets. Do not over tension the belt.

Take-up and jockey rollers

To ensure an optimum service life, the diameter of the roller should be at least twice the size of the spacing of the wires in the belt i.e. 7.26 mm spacing should be at least 15 mm diameter.

Alignment of the drive sprockets

To ensure smooth operation of the belts, the drive sprocket teeth must be in true alignment. This is ensured when using Martens drive sprockets as a mark is machined into the side. If all the drive sprockets are mounted with the mark on the same side then the drive teeth are in line.

Inaccurate pitch of the drive sprockets

When using drive sprockets produced by other manufacturers, it is possible that the pitch and tooth shape are inaccurate. In order to obtain an optimum run of the belt, Martens drive sprockets should be used.

Oscillations during the belt run

Oscillations cause excessive belt wear but often cannot be prevented. To obtain an optimum service life, oscillations should be avoided/minimized.

Faulty connection

The wire rods in the connecting area must be straightened again after establishing the connection. This applies both to connections made by means of an interwoven wire rod as well as when using connection tubes. Drive problems can occur if the wire rods in the connecting area are badly bent.

In addition, the following points must be observed:

Straighten or replace bent or broken wire rods.

Connecting tubes are available for repairs.

It is possible that we may require a longer delivery period to supply a replacement for a worn rod network belt. It is therefore advisable to stock spare lengths. All transfer and drive elements should be checked for wear and replaced, if necessary, before a new rod network belt is drawn into the conveyor. The conveyor must be carefully cleaned.

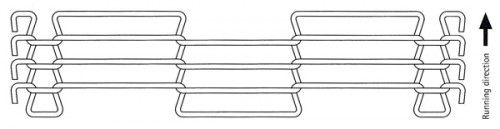

After installing the belt, it must be checked that the belt runs straight and the drive engages correctly. The conveyor must be readjusted without delay if there are any problems. Attention must be paid to the running direction of the rod network belt.

Any build-up of product in/on the rod network belt, the drive and/or transfer elements must be removed without delay.